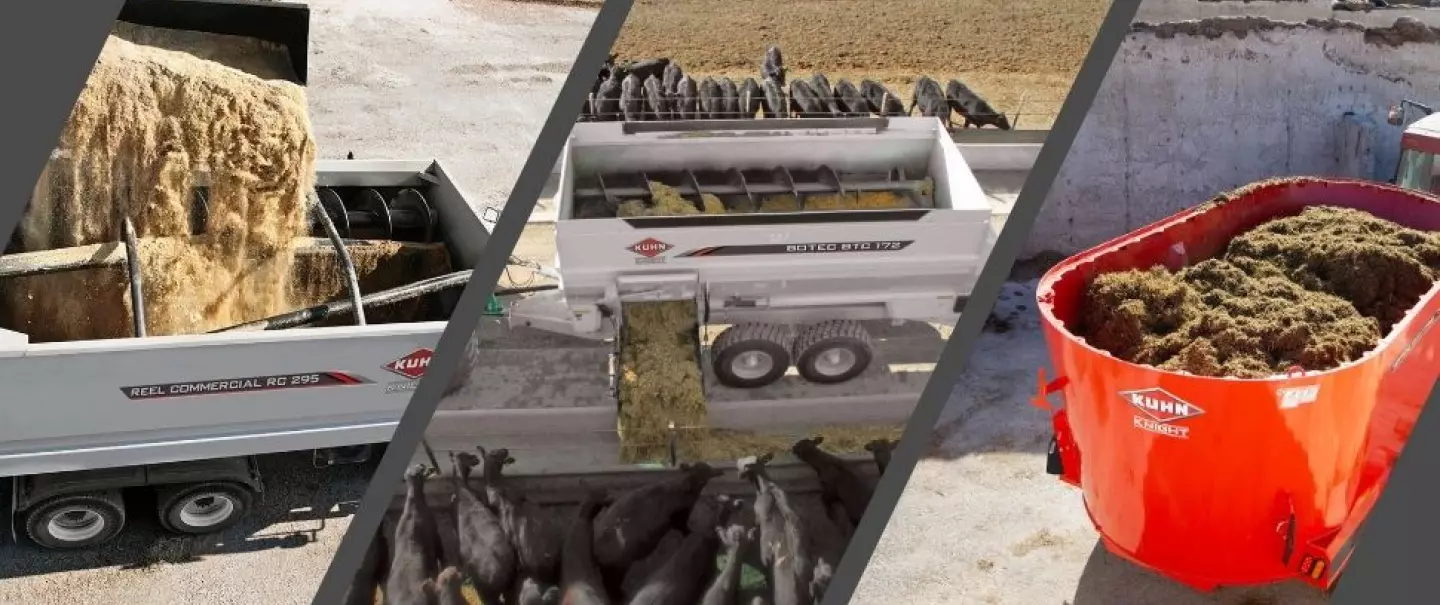

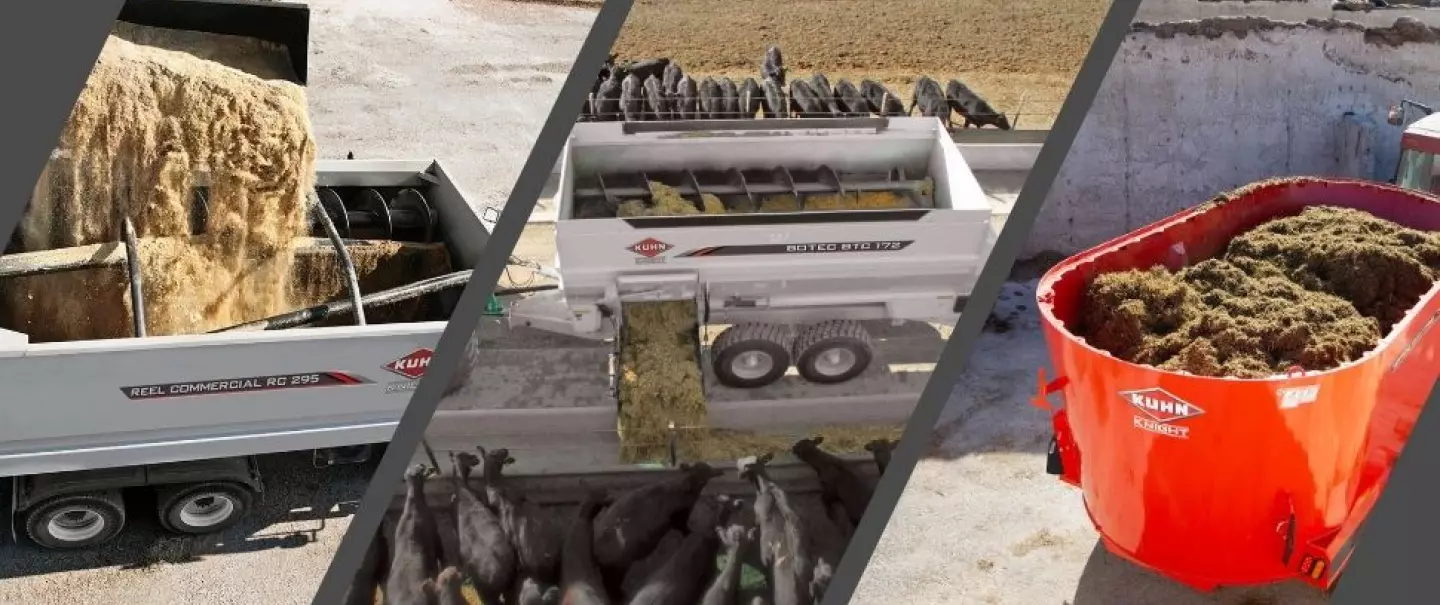

Reel, Horizontal & Vertical Mixers Explained

Reel, horizontal, and vertical TMR mixers each bring a distinct approach to processing and blending feed, giving livestock operations the flexibility to choose the style that best matches their ration...

Reel, horizontal, and vertical TMR mixers each bring a distinct approach to processing and blending feed, giving livestock operations the flexibility to choose the style that best matches their ration...

Single, twin, and triple TMR mixers differ mainly in capacity and efficiency. Single augers suit smaller herds, twin augers handle larger loads with faster mixing, and triple augers deliver high-capac...

TMR mixers come in several configuration types, each designed to match different feeding routines, herd sizes and farm layouts. ...