New from KUHN

Learn more about the newest products from KUHN!

Advance .1 Series Precision Fertilizer Spreader

The new KUHN Advance™ .1 Series precision fertilizer spreaders are engineered to deliver a powerful combination of precise application, high capacity and commercial grade durability. Designed specifically for row crop operations focused on managing input costs and maximizing yield potential, these trailed spreaders build on KUHN’s proven fertilizer spreader technology to achieve highly accurate fertilizer placement under a wide range of field conditions.

SLC 200 Series Side-Discharge Manure Spreader

KUHN North America proudly introduces the new KUHN Knight SLC 200 Series ProTwin® Slinger® commercial manure spreaders, continuing the trusted legacy of rugged construction, superior material breakup, and reliable performance in the toughest conditions. Engineered to handle heavy, sand-laden manure and the widest variety of materials, the SLC 200 Series builds on KUHN’s proven ProTwin Slinger technology for unmatched versatility and durability. Available in both truck-mount and trailer configurations, these spreaders offer capacities from 3,200 to 5,000 gallons to fit a range of operations.

RC 300 Series Reel Commercial TMR Mixer

The new KUHN Knight RC 300 Series is the latest advancement in KUHN mixer technology, building on a long-standing reputation for heavy-duty performance and exceptional quality mixing with low horsepower requirements. With capacities from 500 to 950 ft3, these mixers offer the high-quality mixing producers expect, now enhanced with upgrades that improve durability, simplify maintenance and enhance operator convenience. Available in trailer, truck and stationary models, the RC 300 Series is built to withstand demanding use. Well-suited for dairies, feedlots and a wide range of industrial feeding environments, it delivers consistent, reliable results across diverse applications, helping producers meet today’s challenges with confidence.

9600 Folding Grain Drill

The KUHN 9600 folding grain drill offers a high-efficiency solution built for durability and designed to help farmers seed more acres with less downtime. Available in 30' (9.1 m) and 40' (12.1 m) working widths, the KUHN 9600 offers flexible configuration options to suit a wide range of operational needs. Whether you're managing large acreage or aiming to streamline your seeding process, the KUHN 9600 delivers the capacity, durability and adaptability your operation demands. Farmers can choose from 6",7.5" or 10" (15.2,19.1 or 25.4 cm)row spacing to match specific crop needs and optimize seed placement for maximum yield potential.

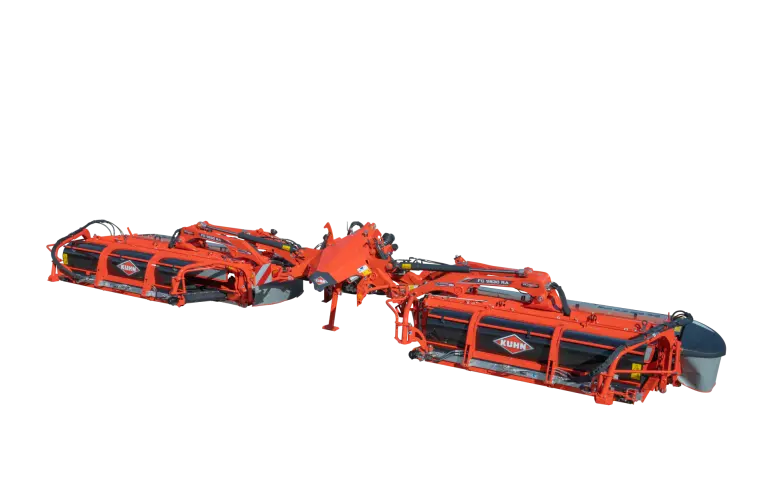

FC 9830 D RA Mower Conditioner/Merger Combination

Kuhn North America, Inc., is pleased to add to the FC 30 D RA Series with the launch of the KUHN FC 9830 D RA. The FC 9830 D RA rear-mounted mower conditioner, with integrated windrow merger, is the perfect solution for haylage and baleage producers, as well as custom operators seeking to save time and reduce fuel consumption by mowing, conditioning and merging in a single pass. Designed to work seamlessly with the FC 3125 DF or FC 3525 DF front-mounted units, the FC 9830 D RA delivers an impressive cutting width of up to 31’10” (9.7 m) in one pass—boosting productivity with industry-leading features.

MM 952 & 1092 Center-Delivery Twin Mergers

With up to 36’ (11 m) of working width, the MM 952 and 1092 center-delivery twin mergers are ideal for larger farms and custom operators who depend on reliable and adaptable hay mergers to increase their operation’s efficiency. These next-generation mergers offer multiple upgrades including ISOBUS controls, hydropneumatics suspension and enhanced pickup components to elevate both machine performance and operator comfort. The MM 952 & 1092 commercial hay mergers are known for their versatility, with the ability to create a uniform windrow, using both center-, side- or split-delivery, in a wide variety of forages.

FB 3125 Fixed Chamber Round Baler

Designed specifically for North American hay and forage producers who prioritize durability, bale density and operational efficiency, the KUHN FB 3125 fixed chamber round baler delivers powerful performance in a compact 4x4 format. Featuring KUHN’s trusted PowerTrack rollers and Integral Rotor technology, it ensures consistent bale formation and smooth crop flow, even in challenging silage or heavy hay conditions. With its rugged build and low-maintenance design, the FB 3125 is the perfect machine for livestock operations, custom balers and mid-sized farms aiming to boost productivity and bale quality across a variety of crops.

Other News

KUHN Product Range

Explore our full lineup of products!

KUHN Kids Holiday Coloring Contest