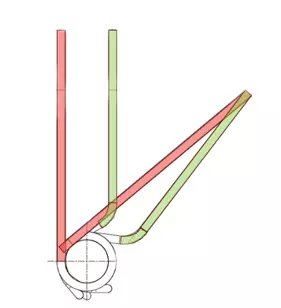

Multiple Delivery Options

The MM 952 and 1092 hay mergers offer eight different delivery options. With the capability to merge crop to the center, left, right, split, these mergers can adapt to any conditions to create windrows to best meet your harvesting needs.