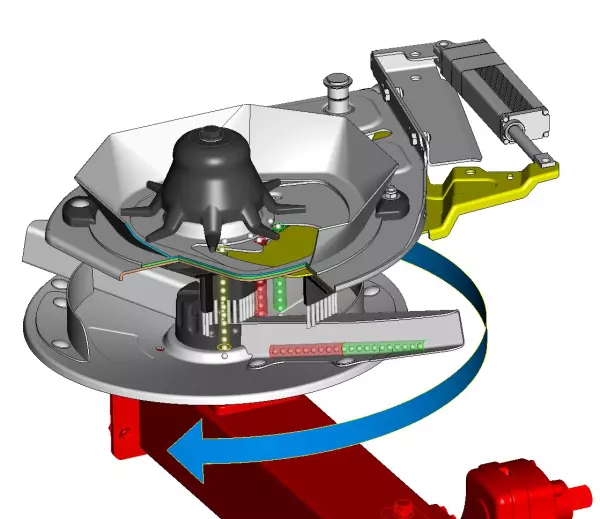

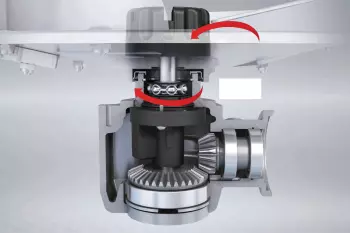

Electronic Mass Flow Control (EMC) System

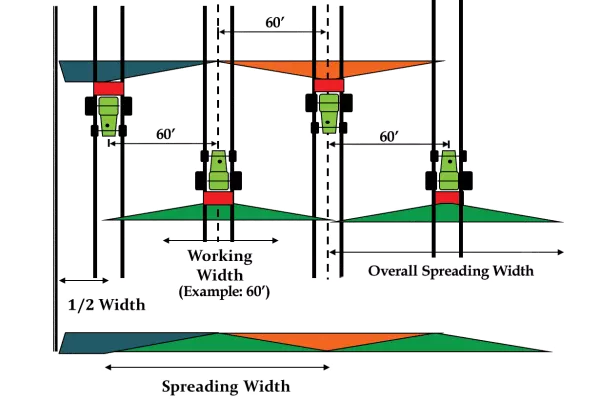

Electronic Mass Flow Control (EMC) is a unique technology, well-established and proven after years of experience. This torque-based system measures and continuously adjusts the application rate on each disc separately for complete flexibility and high precision. EMC technology delivers up to 98% accuracy between the set rate and the actual as-applied rate.