Reel, horizontal, and vertical TMR mixers each bring a distinct approach to processing and blending feed, giving livestock operations the flexibility to choose the style that best matches their ration needs and workflow to deliver quality mixing results.

KUHN offers a wide range of mixers, with features and options to excel in any operation.

Reel (Rotary) Mixers

Gentle, yet thorough mixes with exceptional batch flexibility

Reel mixers use a horizontal reel that gently tumbles feed for top to bottom blending. Dual augers running alongside the reel move opposite of each other, the lower auger continuously charging the discharge door and the top auger providing load leveling.

Performance Highlights

- Lowest horsepower requirement of all mixer types

- Fast blending of even partial loads

- Excellent mixer final cleanout

Key Advantages

- Gentle tumbling action preserves particle size better than any other mixer type

- Thorough blending across any batch size

- Ideal for operations prioritizing ingredient integrity and low operating costs

Important Considerations

Reel mixers' tumbling action thoroughly blends all ingredients, even partial loads, but due to the nature of the reel design, they are sensitive to overfilling, which can compromise mix quality.

Due to the close tolerances between the reel and the tub wall, ingredients must be pre-processed to avoid causing pinch point issues in a reel mixer. Whole bales may not be added.

Horizontal Auger Mixers

Handling even the toughest ingredients

Horizontal auger mixers typically use three or four augers (with four being most common). Lower augers move feed forward while upper augers move it rearward giving front to back mixing action, while the auger flighting direction causes feed to compress in the center giving the bottom to top mixing action seen.

Performance Highlights

- Strong compression action blends even sticky and hard to move ingredients quickly

- Supports rations with up to 25% longstem forage, or 40% if preprocessed

- Also is a great low horsepower mixing option for customers mixing basic silage and grain rations.

Important Considerations

While they can handle some more long stem forage compared to a reel mixer, whole bales cannot be processed in an auger mixer.

Vertical Auger Mixers

Delivering versatility

Available in single, twin, or triple auger configurations, vertical mixers feature an open mixing chamber with no pinch points, allowing them to process entire bales. Augers and auger components interact with the tub wall design to deliver up and down mixing action as well as front to back movement.

What Sets Vertical Mixers Apart

- Open top chambers allow for 100% bale processing capabilities

- Easiest type of mixer to add capacity to, resulting in the largest mixer capacities

- Easier to accommodate different door locations and conveyor options to meet a variety of needs

Important Considerations

While an economical and versatile mixer option, vertical mixers do require more power to mix a similar volume of feed compared to a reel or auger mixer. They can process material down, but that means they can also over-process ingredients left to mix for too long. They perform best when the mixer is fully loaded.

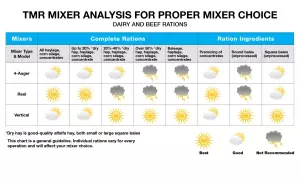

Feed Mixer Recommendation Based on Total Mixed Ration Ingredients

Tips for Choosing the Right TMR Mixer

Choosing the right TMR mixer depends on the type of ration you feed and the ingredients included. This chart provides a quick reference to help you match mixer types—4-Auger, Reel, or Vertical—with different ration compositions and ingredient handling needs.

- Complete Rations: Shows how each mixer performs with varying levels of dry hay, haylage, corn silage, and concentrates.

- Ration Ingredients: Indicates suitability for premixes, round bales, and square bales.

The icons represent performance:

- ☀️ Best – Ideal choice for this ration type

- 🌤 Good – Acceptable, but not optimal

- 🌩 Not Recommended – Avoid for this application

Use this guide as a general reference. Individual rations vary by operation, so always consider your specific feeding program when selecting a mixer.

Find the Right Mixer for Your Operation

Whether you need to gently mix a feedlot ration, process bales for your cows in off pasture, or uniformly mix a large amount feed for your dairy herd, a well-matched mixer is essential to helping you meet your operational goals.

If you’d like help choosing the best mixer for your feeding program, contact your local KUHN dealer today!