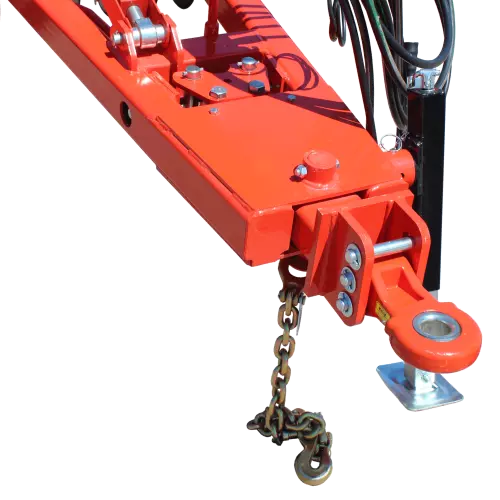

| Combination CAT III - 1-1/2" Pin and C Clevis - 1 1/4" Pin | Combination CAT III - 1-1/2" Pin and C Clevis - 1 1/4" Pin | Articulating Ball, CAT IV, 2" Pin | Articulating Ball, CAT IV, 2" Pin | Articulating Ball, CAT IV, 2" Pin | Articulating Ball, CAT IV, 2" Pin | Articulating Ball, CAT IV, 2" Pin |

| Mechanical Fore / Aft Adjustment, Level - Lift Tongue | Mechanical Fore / Aft Adjustment, Level - Lift Tongue | Mechanical Fore / Aft Adjustment, Level - Lift Tongue | Mechanical Fore / Aft Adjustment, Level - Lift Tongue | Mechanical Fore / Aft Adjustment, Level - Lift Tongue | Mechanical Fore / Aft Adjustment, Level - Lift Tongue | Guardian Hitch™ (Cushion Tongue) Level-Lift |

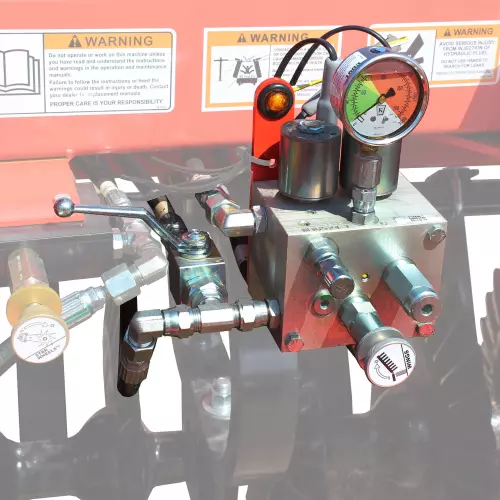

| Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Single Point Depth Control, Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

| Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting | Hydraulic Lock Valves (Lift and Wing Fold), Slow Moving Vehicle Sign, High Visibility LED Lighting |

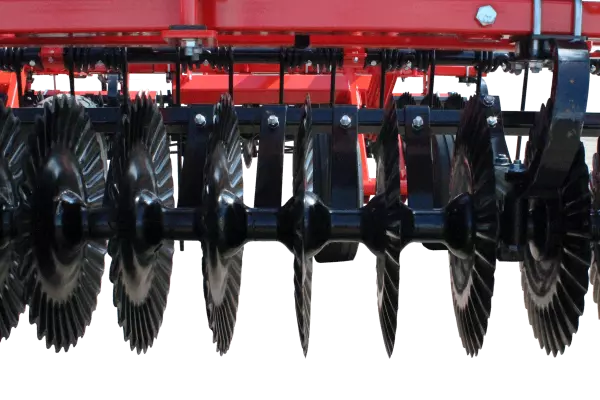

| Excalibur® VT Blades - 22" Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades - 22" Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades - 22" Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades - 22" Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades - 22" Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades - 22" Diameter, 6mm, 32-Flute, Reversed Crimped Center | Excalibur® VT Blades - 22" Diameter, 6mm, 32-Flute, Reversed Crimped Center |

| 1-¾" Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms - C-Type 1-¼" x 2-½", 6" Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾" Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms - C-Type 1-¼" x 2-½", 6" Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾" Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms - C-Type 1-¼" x 2-½", 6" Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾" Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms - C-Type 1-¼" x 2-½", 6" Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾" Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms - C-Type 1-¼" x 2-½", 6" Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾" Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms - C-Type 1-¼" x 2-½", 6" Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench | 1-¾" Round Diameter Alloy Tie Rod, Rock-Flex™ Bearing Arms - C-Type 1-¼" x 2-½", 6" Bell Diameter Ductile Iron Spools, Cast Housing PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings, Trash Bars, Tie Rod Wrench |

| Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Mechanical Adjustment 1 to 8 Degrees | Hydraulic Adjustment 1 to 8 Degrees |

| Not Applicable | Not Applicable | None | None | None | None | None |

| Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle | Manual with 3 to 1 Ratio Turnbuckle |

| Walking Beams With Spherical Pivot Bearings, Slip-in Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 | Walking Beams With Spherical Pivot Bearings, Slip-in Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 340/60R16.5 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 340/60R16.5 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 380/55R16.5 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 440/55R18 | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (4) 440/55R18 |

| Not Applicable | Not Applicable | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 6-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (2) 340/60R16.5 per Wing (2) | Walking Beams With Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Hubs, (2) 280/70R15 per Wing (4) |

| Not Applicable | Not Applicable | (2) 4" x 40" Adjustable Constant-Flow Hydraulic Down Pressure | (2) 4" x 40" Adjustable Constant-Flow Hydraulic Down Pressure | (4) 4" x 40" Adjustable Constant-Flow Hydraulic Down Pressure | (4) 4" x 40" Adjustable Constant-Flow Hydraulic Down Pressure | (4) 4" x 40" (4) 4-1/2" x 16" Adjustable Constant-Flow Hydraulic Down Pressure |

| (2) 4" x 10" | (2) 4" x 10" | Center: (2) 4" x 10"

Wings: (2) 3-¾" x 10" | Center: (2) 4" x 10"

Wings: (2) 3-¾" x 10" | Center: (2) 4 -¼" x 10"

Wings: (2) 4" x 10" | Center: (2) 4 -¼" x 10"

Wings: (2) 4" x 10" | Center: (2) 4-¼" x 10"

Inner Wing: (2) 4" x 10"

Outer Wing: (2) 3-¾" x 10" |

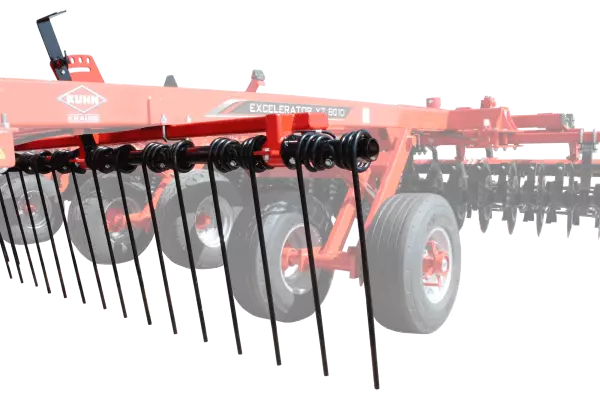

| 5/8" x 27" Tines on 7" Spacing | 5/8" x 27" Tines on 7" Spacing | 5/8" x 27" Tines on 7" Spacing | 5/8" x 27" Tines on 7" Spacing | 5/8" x 27" Tines on 7" Spacing | 5/8" x 27" Tines on 7" Spacing | 5/8" x 27" Tines on 7" Spacing |

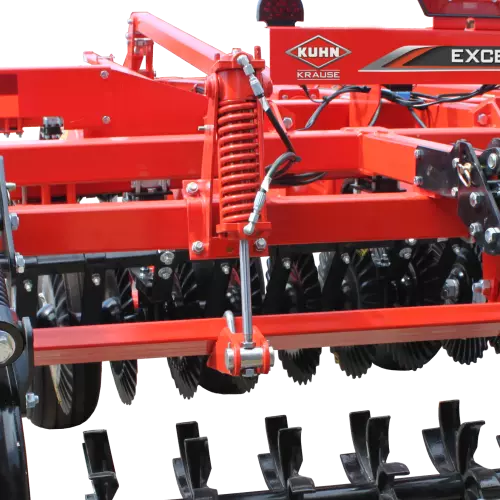

| 1-½" Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8" Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½" Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8" Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½" Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8" Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½" Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8" Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½" Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8" Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½" Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8" Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings | 1-½" Round Diameter Alloy Tie Rod, Rigid Bearing Arms, 8" Spacing, 6 Degree Angle, Manual Spring Adjustable Gangs, Flangette PEER® TILLXTREME™ No-Daily Grease Maintenance Bearings |

| Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings | Flat Bar Spiral Rod HD Reels, No-Daily Grease Maintenance Bearings |

| None | None | None | None | None | None | None |