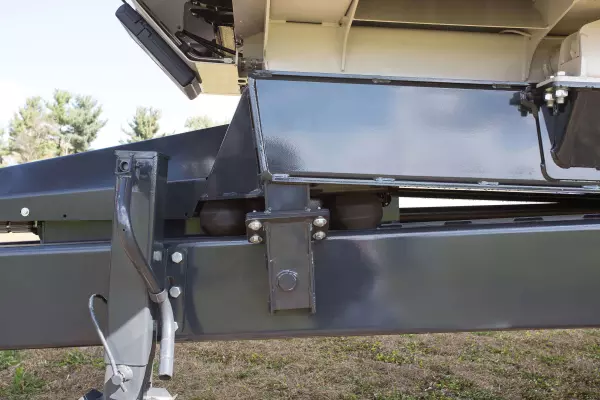

All-Steel, Welded Construction

The HPX 195 features a 10-gauge sidewall with an added 1/4” (.64 cm) poly liner. An all-steel welded construction provides a solid framework. Formed channel side stakes provide support for the box sidewalls. A sidewall flare increases ease of loading and allows the operator to maintain a comfortable distance from the unit while loading.