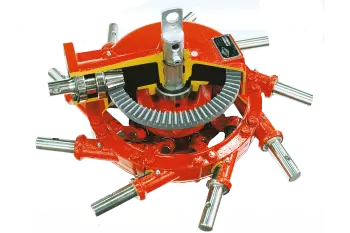

Fully Enclosed Gear Case

The fully enclosed single-stage gearbox is grease filled and sealed to be maintenance free ensuring a long life. For additional durability, the tine arm holders are fixed on both the upper and lower gearcase covers. The gearbox houses a cam track with a profile optimized for fast lifting action that creates a well-formed windrow while maintaining high clearance over the windrow.