MacDon Integration

The self-propelled mounted merger head design brings the work in front of the operator, which increases productivity of an operation and enhances maneuverability. The merger head positioned in front of the power unit eliminates driving on crop, preserving forage value. The increased visibility of the merger head allows the operator to quickly spot and remedy potential issues, thus limiting downtime.

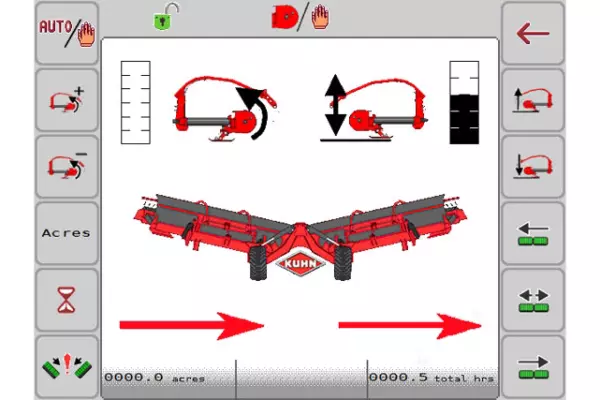

The KUHN Merge Maxx self-propelled mounted mergers are compatible with multiple MacDon power units. The compatibilities are MacDon M Series (M155, M205), M1 Series (M1170, M1240), and M2 Series (M2170, M2260).

The KUHN Merge Maxx self-propelled mounted mergers are compatible with multiple MacDon power units. The compatibilities are MacDon M Series (M155, M205), M1 Series (M1170, M1240), and M2 Series (M2170, M2260).