| CAT IV, 2-Hole Mount | CAT IV, 2-Hole Mount | CAT IV, 3-Hole Mount | CAT IV, 3-Hole Mount | CAT V, 3-Hole Mount |

| Adjustable Level-Lift Tongue | Adjustable Level-Lift Tongue | Guardian Hitch™ (Cushion Tongue) Adjustable Level-Lift Tongue | Guardian Hitch™ (Cushion Tongue) Adjustable Level-Lift Tongue | Guardian Hitch™ (Cushion Tongue) Adjustable Level-Lift Tongue |

| Mechanical Fore / Aft Adjustment | Mechanical Fore / Aft Adjustment | Mechanical Fore / Aft Adjustment | Mechanical Fore / Aft Adjustment | Mechanical Fore / Aft Adjustment |

| Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Cylinders, Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

| (4) 4" x 32" Cylinders | (4) 4" x 40" Cylinders | (4) 4" x 40" Cylinders | (4) 5" x 40" Cylinders, (2) 4" x 24" Cylinders, & (2) 5" x 24" Cylinders" | (4) 5" x 40" Cylinders & (4) 5" x 24" Cylinders" |

| (2) 4.5" x 12" Cylinders & (2) 4.25" x 12" Cylinders | (2) 4.5" x 12" Cylinders & (2) 4.25" x 12" Cylinders | (2) 4.5" x 12" Cylinders & (2) 4.25" x 12" Cylinders | (2) 4.5" x 12" Cylinders & (2) 4.25" x 12" Cylinders | (2) 4.5" x 12" Cylinders & (2) 4.25" x 12" Cylinders |

| Single-Point Hydraulic | Single-Point Hydraulic | Single-Point Hydraulic | Single-Point Hydraulic | Single-Point Hydraulic |

| Excalibur ® CT Blades - 22" 5mm, 32-Flute Shallow Concavity | Excalibur ® CT Blades - 22" 5mm, 32-Flute Shallow Concavity | Excalibur ® CT Blades - 22" 5mm, 32-Flute Shallow Concavity | Excalibur ® CT Blades - 22" 5mm, 32-Flute Shallow Concavity | Excalibur ® CT Blades - 22" 5mm, 32-Flute Shallow Concavity |

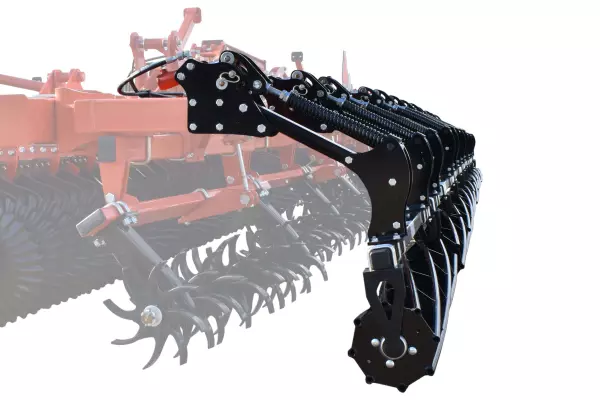

| Compound Angle with Isolator Torsion Cord Individual Mount | Compound Angle with Isolator Torsion Cord Individual Mount | Compound Angle with Isolator Torsion Cord Individual Mount | Compound Angle with Isolator Torsion Cord Individual Mount | Compound Angle with Isolator Torsion Cord Individual Mount |

| Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blade | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blade | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blade | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blade | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blade |

| Single Row Adjustable Angle Tine Bar with 5/8" x 30" Tines on 9" Spacing | Single Row Adjustable Angle Tine Bar with 5/8" x 30" Tines on 9" Spacing | Single Row Adjustable Angle Tine Bar with 5/8" x 30" Tines on 9" Spacing | Single Row Adjustable Angle Tine Bar with 5/8" x 30" Tines on 9" Spacing | Single Row Adjustable Angle Tine Bar with 5/8" x 30" Tines on 9" Spacing |

| Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 380/55R16.5 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 380/55R16.5 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 480/45R17 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 480/45R17 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 480/45R17 |

| Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 380/55R16.5 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 380/55R16.5 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 480/45R17 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 480/45R17 | Walking Beams with Spherical Pivot Bearings, Slip-In Spindles, 8-Bolt Heavy-Duty Regreaseable Hubs, (4) 480/45R17 |

| (1) Adjustable, Front Mounted, Pivoting Stabilizer Wheel per Wing, 280/70R15 Tire | (1) Adjustable, Front Mounted, Pivoting Stabilizer Wheel per Wing, 280/70R15 Tire | (1) Adjustable, Front Mounted, Pivoting Stabilizer Wheel per Wing, 280/70R15 Tire | (1) Adjustable, Front Mounted, Pivoting Stabilizer Wheel per Wing, 280/70R15 Tire | (1) Adjustable, Front Mounted, Pivoting Stabilizer Wheel per Wing, 280/70R15 Tire |

| Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant-Flow 24/7® Heavy-Duty Round Rod Reel with Hydraulic Lift Featuring PEER® TILLXTREME™ Maintenance-Free Bearings | Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant-Flow 24/7® Heavy-Duty Round Rod Reel with Hydraulic Lift Featuring PEER® TILLXTREME™ Maintenance-Free Bearings | Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant-Flow 24/7® Heavy-Duty Round Rod Reel with Hydraulic Lift Featuring PEER® TILLXTREME™ Maintenance-Free Bearings | Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant-Flow 24/7® Heavy-Duty Round Rod Reel with Hydraulic Lift Featuring PEER® TILLXTREME™ Maintenance-Free Bearings | Star Wheel™ Gangs Mounted on 6 Degree Angles with Hydraulic Constant-Flow 24/7® Heavy-Duty Round Rod Reel with Hydraulic Lift Featuring PEER® TILLXTREME™ Maintenance-Free Bearings |