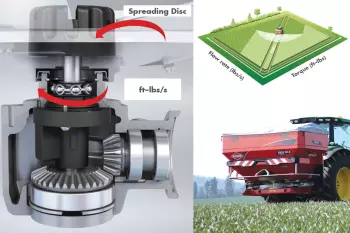

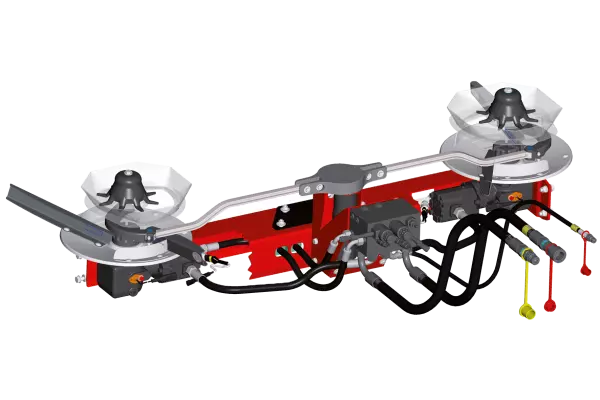

Coaxial Distribution Adjustment System (CDA)

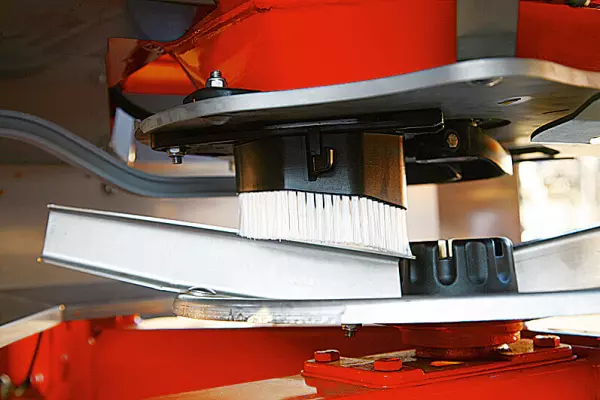

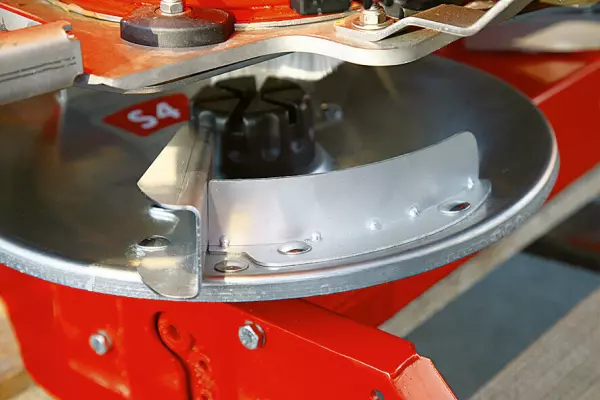

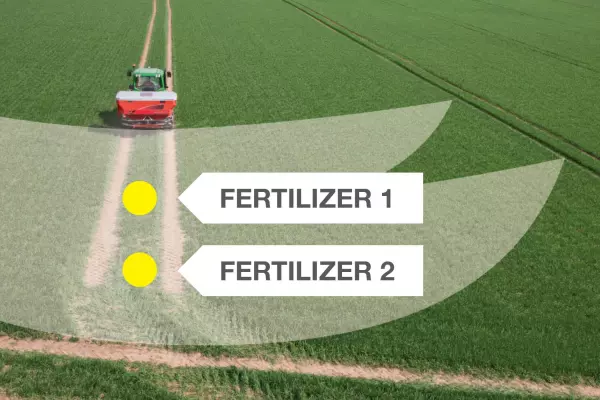

- The pivoting hopper base enables quick adaptation to various fertilizers and working widths by adjusting the drop point of the fertilizer onto the spreading discs.

- Specially designed metering outlets, close to the center of the discs, allow multiple supply points to the paddles. This helps ensure constant fertilizer flow and an even spread pattern.

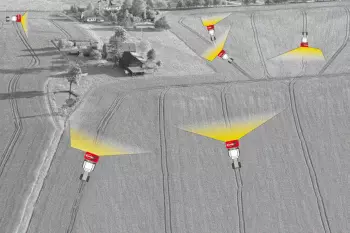

You can modify the working width in a few seconds by simply changing the drop point of the fertilizer onto the disc. This is done without any tools by pivoting the base – from the cab via the ISOBUS display. No paddles have to be adjusted and no manual contact with the fertilizer is required.