High-Quality Tines

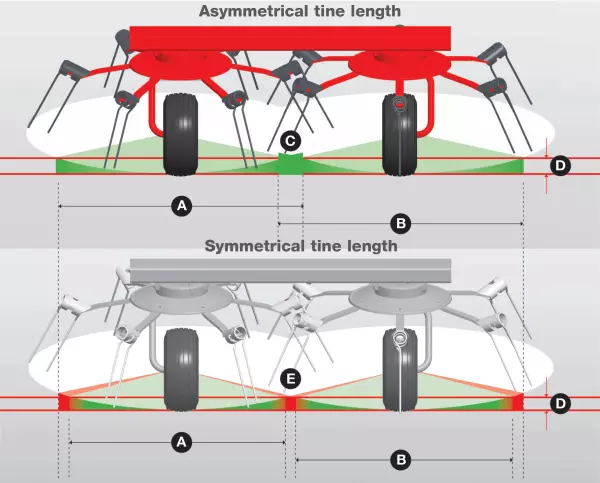

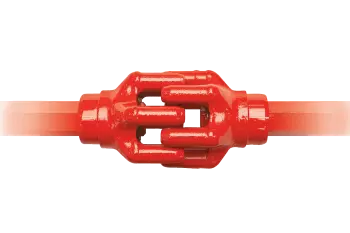

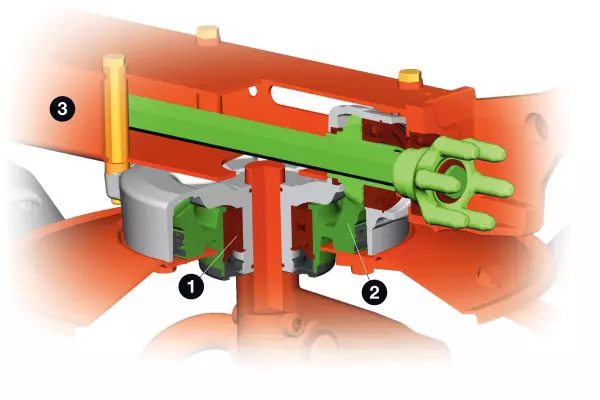

When it comes to tines that actually engage the crop, KUHN leaves nothing to chance: top-quality raw material has been wound into four coils with long tine fingers, giving you exceptional reliability. A defined attachment system to the arms results in an unmatched design life of at least 180,000 cycles. This provides several hundred hours of work before tine replacement is necessary. Asymmetrical tine finger length means both fingers engage the crop equally and sooner for a more consistent pickup. The tine guards prevent accumulation of debris around the coils and help retain broke tines from entering the tedded crop to minimized possible damaging harvesting equipment.