Masterdrive® GIII Gearbox

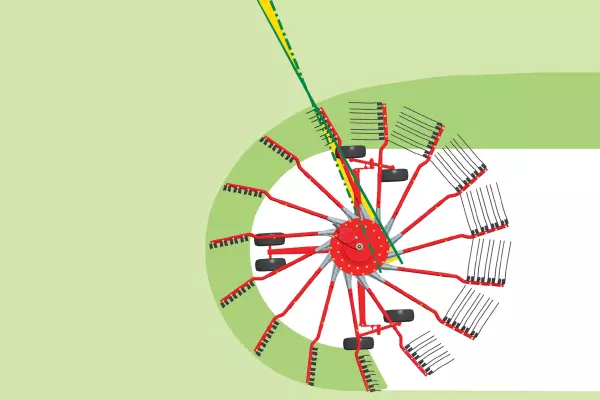

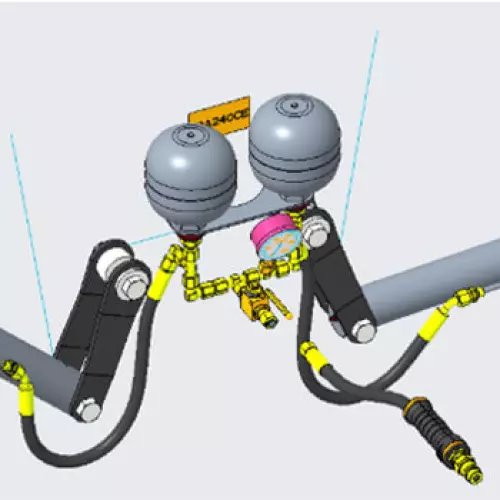

The patented KUHN Masterdrive® GIII double-reduction gearbox is designed for heavy crops, tough field conditions, and intensive use. Key components have been improved to build lighter, yet stronger rotors such as: aluminum alloy housings, optimized cam track minimizing force on the follower bearing, larger follower bearing diameter reducing rotation speed and pressure on the cam, tine arms with large-dimension bearings, sturdier pivoting tine support shaft, reinforced main shaft, and reinforced mounting of tine arms on tine holders. The Masterdrive GIII’s ability to move heavy crop, handle dry hay gently, and create a uniform windrow is unrivaled in the industry.